CNC Pipe Bending Machines (A-type)

Features:

Features:

1. Adopts PLC and touch screen.

2. Drive by hydraulics.

3. After input the bending angles, the machine can bend automatically.

4. Storage: 9 bends per part and 500 groups programs.

5. Automatic compensation function.

6. Calculator function.

7. Prevention of ovality and wall thickness reduction functions

8. Powerful water cooling system allows the machine working in tropical area.

9. Air cooling system (optional).

10. Material lubrication function (optional).

PLC Pipe Bending Machines (B-type)

Features:

1. Adopts PLC and switch to control the machine.

2. Drive by hydraulics.

3. 2 bends per part.

4. Calculator function.

5. Powerful water cooling system allows the machine working in tropical area.

machine working in tropical area.

6. Mandrel lubrication function (optional).

7. Air cooling system(optional)

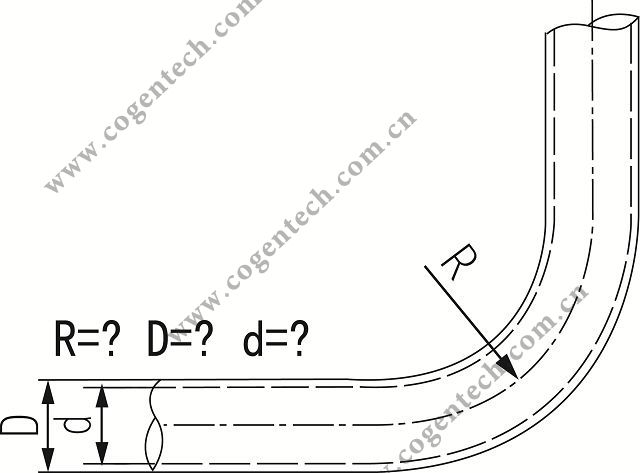

How to order moulds/Dies:

Moulds on request if you can

supply tube drawings or follow

parameters to us!

|

Order No.

|

8-20-00

|

8-20-02

|

8-20-04

|

8-20-06

|

8-20-08

|

8-20-10

|

8-20-12

|

8-20-14

|

|

MODEL (A/B type)

|

Unit

|

KPB-20

|

KPB-25

|

KPB-38

|

KPB-50

|

KPB-63

|

KPB-75

|

KPB-89

|

KPB-100

|

|

Max. round pipe

|

mm

|

19.05

|

25.4

|

38.1

|

50.8

|

63.5

|

76.2

|

88.9

|

101.6

|

|

Max. wall thickness

|

mm

|

1.5

|

1.5

|

2

|

2.5

|

3

|

3

|

4

|

4

|

|

Max. stainless steel pipe

|

mm

|

12.7

|

19.05

|

31.75

|

44.45

|

63.5

|

76.2

|

88.9

|

101.6

|

|

Max. wall thickness

|

mm

|

1.5

|

1.5

|

1.5

|

2

|

1.5

|

1.5

|

2

|

2

|

|

Max. square pipe

|

mm

|

14

|

20

|

30

|

40

|

50

|

60

|

70

|

80

|

|

Max. wall thickness

|

mm

|

1.4

|

1.4

|

1.5

|

2

|

2.5

|

2.5

|

3

|

3.8

|

|

Max. round bar

|

mm

|

12

|

18

|

25

|

32

|

38

|

45

|

55

|

60

|

|

Max. bending radius

|

mm

|

100

|

100

|

160

|

200

|

270

|

280

|

350

|

400

|

|

Bending angle

|

degree

|

0~190°

|

|

Mandrel working distance

|

mm

|

1200

|

1500

|

1900

|

2300

|

2800

|

3000

|

3300

|

3600

|

|

Max. bending speed

|

deg/sec

|

120

|

100

|

80

|

50

|

40

|

25

|

20

|

16

|

|

Bending accuracy

|

degree

|

±0.15°

|

|

Hydraulic motor power

|

KW

|

2.2

|

4

|

4

|

5.5

|

7.5

|

7.5

|

11

|

15

|

|

Max.working pressure

|

Mpa

|

14

|

14

|

14

|

14

|

17.5

|

17.5

|

17.5

|

7.5

|

|

Hydraulic tank capacity

|

L

|

100

|

100

|

100

|

120

|

150

|

190

|

210

|

240

|

|

Total width

|

mm

|

600

|

600

|

650

|

750

|

800

|

1050

|

1200

|

1400

|

|

Total height

|

mm

|

1000

|

1100

|

1150

|

1260

|

1300

|

1250

|

1300

|

1400

|

|

Total length

|

mm

|

1850

|

2200

|

2600

|

3000

|

3500

|

4350

|

4800

|

4800

|

|

Weight

|

kg

|

450

|

680

|

850

|

950

|

1400

|

2500

|

3000

|

4600

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order No.

|

8-20-16

|

8-20-18

|

8-20-20

|

8-20-22

|

8-20-24

|

8-20-26

|

8-20-28

|

8-20-30

|

|

MODEL (A/B type))

|

Unit

|

KPB-120

|

KPB-150

|

KPB-168

|

KPB-180

|

KPB-219

|

KPB-250

|

KPB-273

|

KPB-325

|

|

Max. round pipe

|

mm

|

114.3

|

152.4

|

168.3

|

180

|

219.1

|

244.5

|

273

|

323.9

|

|

Max. wall thickness

|

mm

|

5.5

|

8

|

10

|

11

|

14

|

15

|

15

|

25

|

|

Max. stainless steel pipe

|

mm

|

114.3

|

152.4

|

168.3

|

180

|

219.1

|

244.5

|

273

|

323.9

|

|

Max. wall thickness

|

mm

|

2.5

|

3.5

|

4

|

4.5

|

6

|

6.5

|

6.5

|

12

|

|

Max. square pipe

|

mm

|

90

|

120

|

150

|

160

|

200

|

220

|

240

|

260

|

|

Max. wall thickness

|

mm

|

4

|

5

|

6

|

7

|

8

|

10

|

12

|

16

|

|

Max. round bar

|

mm

|

70

|

90

|

110

|

120

|

130

|

145

|

160

|

230

|

|

Max. bending radius

|

mm

|

500

|

600

|

700

|

750

|

800

|

850

|

900

|

1100

|

|

Bending angle

|

degree

|

0~190°

|

|

Mandrel working distance

|

mm

|

4800

|

6000

|

6500

|

7000

|

7800

|

8500

|

9000

|

9000

|

|

Max. bending speed

|

deg/sec

|

10

|

6

|

4

|

3

|

2.5

|

2.5

|

2.5

|

1.5

|

|

Bending accuracy

|

degree

|

±0.15°

|

|

Hydraulic motor power

|

KW

|

15

|

22

|

30

|

30

|

45

|

75

|

75

|

75

|

|

Max. working pressure

|

mpa

|

17.5

|

|

Hydraulic tank capacity

|

L

|

440

|

450

|

770

|

850

|

1500

|

2000

|

2300

|

3000

|

|

Total width

|

mm

|

1650

|

2200

|

2250

|

2500

|

3000

|

3000

|

3900

|

4800

|

|

Total height

|

mm

|

1550

|

1750

|

1950

|

2150

|

2500

|

2850

|

3300

|

4800

|

|

Total length

|

mm

|

6700

|

8100

|

9200

|

10500

|

11300

|

12000

|

12600

|

14500

|

|

Weight

|

kg

|

7500

|

13500

|

16000

|

21000

|

36000

|

48000

|

65000

|

90000

|

![]()